loading

GET.GX.

GET INDUSTRY | TRAILERBULL

GET.GX.

| Thickness: | |

|---|---|

| Availability: | |

| Quantity: | |

Product Description

Dry Freight Composite Sandwich Panels | |||

| 1. Instruction of the Dry Freight Composite Sandwich Panels | |||

Dry Freight Transport is still the important delivery method in the logistics, to get better relations with the Environments, we developed three types of composite Sandwich panels to make the suitable box lighter and stronger. The Plywood Boned Panel, The XPS Boned Panel and The Honeycomb Boned Panel, it allows for maximum diversity of cabin size choices and provides the option to adjust strength requirements through additional plys or wall thickness. The Finished box has superior strengthen performance with an approximate bending strengthen to 10Mpa, Compression Strength to 1.5Mpa. Typical panels are a solid core 3-ply that is ultra-high strength, low weight, self-supporting. 1. Plywood, XPS, Honeycomb or customized Core Material with FRP , Aluminum , CFRT , PPGI cover Skin can meet almost of the Dry Freight Logistics Demands. 2. Mono blocked Installation Extrusion make the Assembling at Site easy and quick. Flat-Packed shipment to save the high Freight cost. 3. Composite new Materials and structure to save the 50% weight and get the best strength than the Metal Box. 4. Different Materials Panel Cooperate in one box to get more Functions give more surprise to the world. | |||

| |||

| 2. General Of the Structural Composite Sandwich panels | |||

| Max. Length of the Panel Kits | 14750mm | ||

| Max Wideth of the panel Kits | 3200mm | ||

| Thickness of the Panel Kits | 30,50,,83.5,105,mm135mm | ||

| K Value | |||

| Tensile strength | >180MPa | ||

| Flexural strength | >220MPa | ||

| Barcol hardness | 24.6MPa | ||

Extrusion : The Monoblock Aluminum Extrusion(20-20,30-30,50-50)give an extremely Modular quick installation.,

Wall Panels: Mutil Options for the Cover & Corn Material meet all the Box demands.

Floor: 3mm Checked Steel Plate with Subchassis.

Roof : FRP sheet or XPS Structural Composite sandwich panles

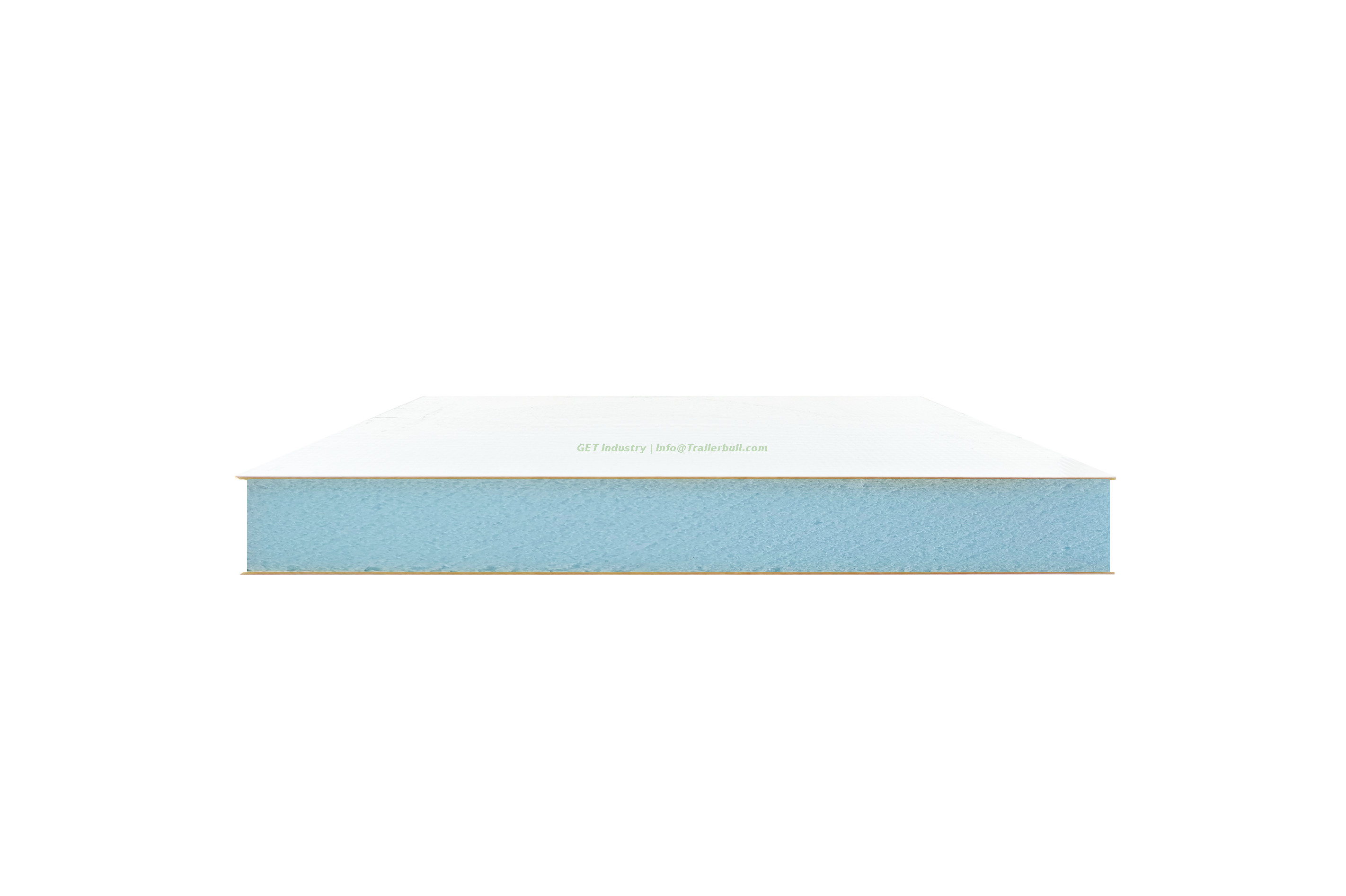

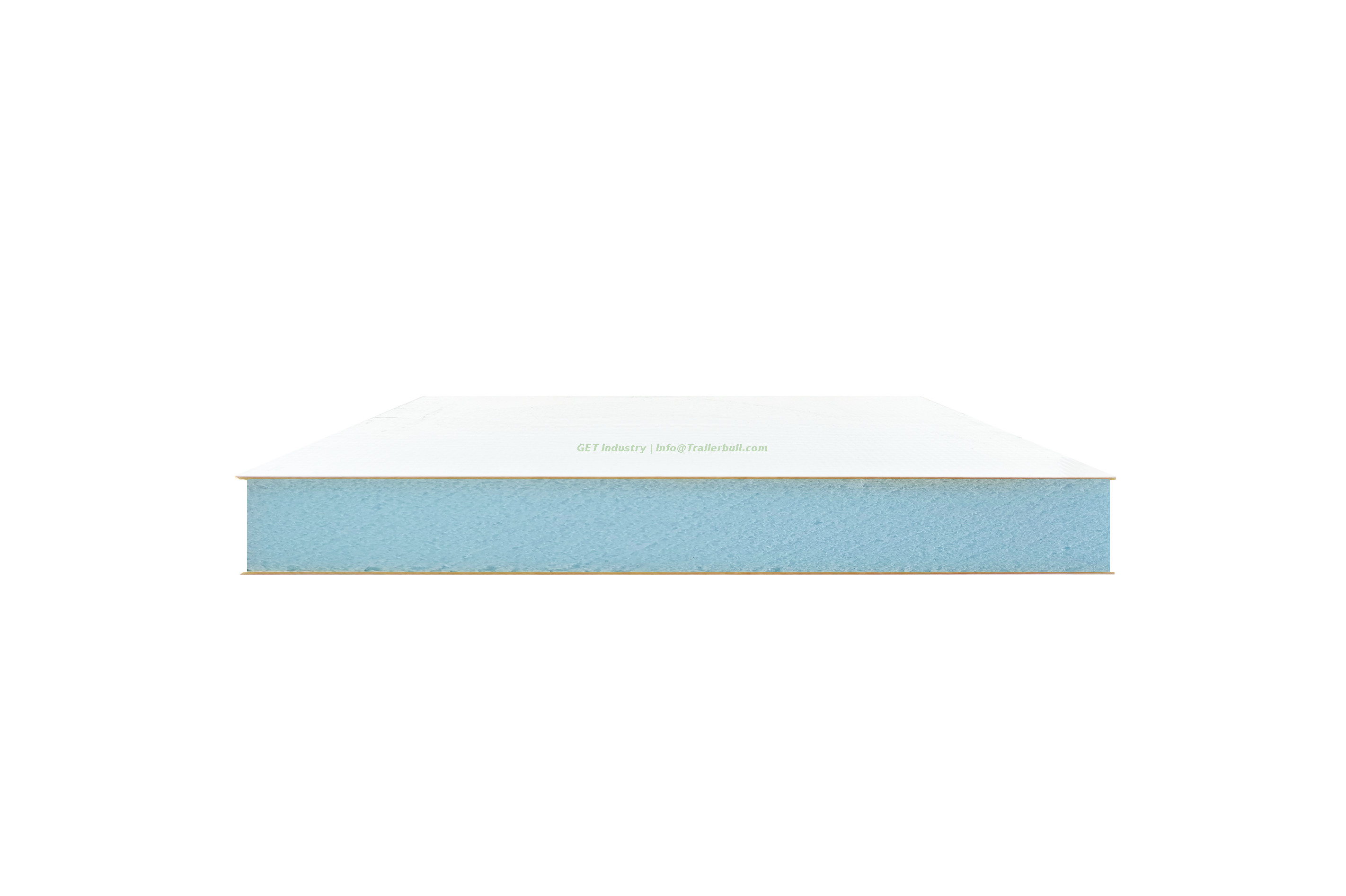

PP Honeycomb Boned Panel

Plywood Boned Panel

XPS Boned Panel

| FRP can let the body get a good insulation function and light dead weight, we also Using an adhesive joining process with LAMILUX to employ the fiberglass sheets to construct boxes with completely vapour diffusion-tight surfaces to get better insulation and balance temperature inside. | |||

| Core Thermal Polyrethane Foam All panels, Floor & Roof of the box will be insulated with POLYURETHANE foam (PU) of density 40KG~45/M3, which can carry the Thermal Conductivity value 0.3kcal/M3. | |||

| KOMMERLING Two component reaction adhesive | |||

| Model Values | LAMILUX High Impact | LAMILUX Woven Fabric Gelcoat | LAMILUX High Gloss 4000 |

| Thickness | 1.4 mm | 2.0 mm | 1.7mm |

| Weight | 2250 g/㎡ | 2650 g/m2 | 2340 g/㎡ |

| Glass content | 48-52 % | 27-29 % | 20-24% |

| Flexural strength | 305 N/m㎡ | 170N/mm | 100 N/m㎡ |

| Flexural emodulus | 8550 N/m㎡ | 11700 N/mm2 | 4000N/m㎡ |

| Tensile strength | 240 N/m㎡ | 80 N/mm | 55 N/m㎡ |

| Tensile emodulus | 14700 N/m㎡ | 8100 /mm2 | 6000 N/m㎡ |

| Impact strength | 82 KJ/㎡ | ||

| Advantage of LAMILUX panel | Benefit | ||

| 1. Computer manufacturing process VS hand layup | High impact resistance | ||

| 2. Fiber reinforce plastic VS metal panel | Better heat insulation | ||

| 3. Constant gloss level | Good surface aspect | ||

| 4. Very consistent gelcoat-thicknesses | No cracks | ||

| 5. FRP-sheets lie flat | No curl | ||

| 6. Less translucency for sunlight and also UV-light | No color variation | ||

| 7. Anti slip-PES floor | Abrasion resistance | ||

| 8. TUV &ATP certificate | High quality and Food safety | ||

LamiLux High Glossy FRP

LamiLux High Impact FRP

LamiLux Super Plus FRP

LamiLux Gewebe Plus FRP

LamiLux Gewebe Plus FRP